Concept Development: We begin by discussing your product requirements—size, capacity, shape, mouth diameter, material, and application. Our design team then creates detailed 3D models and provides a 3D-printed prototype for your approval, ensuring alignment on dimensions, aesthetics, and functionality.

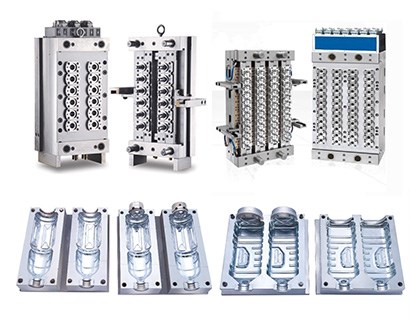

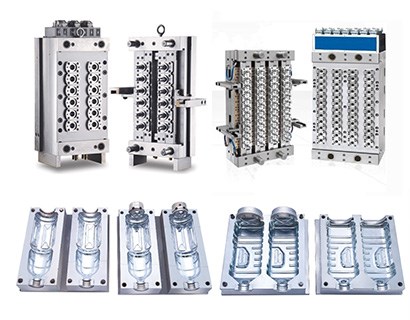

Mold Development & Optimization: Mold production is assigned based on project scope, timeline, and product type. Costs vary depending on container volume, structural complexity (e.g., integrated handles), and special requirements such as thick walls or post-molding finishing. Each mold undergoes strict quality checks, and sample validation ensures performance before full production.

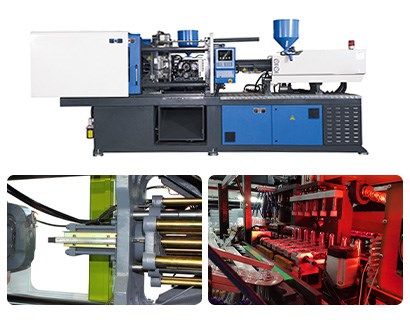

Production: Approved molds are transferred to our manufacturing facilities. Production speed depends on the molding method (blow molding or stretch blow molding), number of cavities, and cycle time, ensuring efficient and scalable output.