Essential Insights for Brands Considering Custom Mold Glass Bottles Prior to Placing an Order

Essential Insights for Brands Considering Custom Mold Glass Bottles Prior to Placing an Order

Bespoke glass bottles present a remarkable chance for brands to differentiate themselves in their industries. These bottles serve purposes beyond merely containing liquids; they function as effective marketing and branding instruments as well as unique design elements. Whether you are a distillery aiming to highlight your distinctive whisky blend or a winery wanting to create an eye-catching presentation for your red wine, custom-designed glass bottle packaging offers unparalleled potential. In this detailed guide, we will cover everything you need to consider before investing in custom glass bottle molds, ensuring that your project achieves optimal aesthetics, functionality, and long-term value.

Why Custom Mold Glass Bottles Matter for Brand Identity

In the bustling and rapidly evolving marketplace of today, differentiating oneself is essential. Packaging frequently serves as the initial interaction consumers have with your product, making it a vital component of your brand identity. Custom-molded glass bottles enable businesses to:

- Create a distinctive and eye-catching display on store shelves

- Convey your brand’s essence and principles through design, heft, and finishing touches

- Foster consumer trust and project an image of sophistication

- Set yourself apart from competitors in terms of both design and intent.

Bespoke bottles serve as tangible symbols of your brand's identity. Take, for instance, an artisanal gin producer; they could significantly enhance their appeal with a tailored embossed gin bottle that showcases a captivating design, complete with detailed embossing and a distinctive closure. Such personalized elements not only elevate the product's worth but also strengthen the brand's visibility and customer loyalty among discerning buyers.

Understanding the Custom Mold Process

Crafting bespoke glass molds involves a complex series of steps that merges artistic vision with exacting production techniques. Below is an in-depth overview of the entire procedure:

1. Concept Development

Start by engaging in conversations about generating ideas, incorporating visual aids and hand-drawn design concepts along with precise CAD renderings that embody your brand's identity.

2. 3D Modeling and Prototyping

Sophisticated 3D software enables the generation of digital prototypes, helping users to see the bottle's dimensions, design features, and how well it fits with various closures.

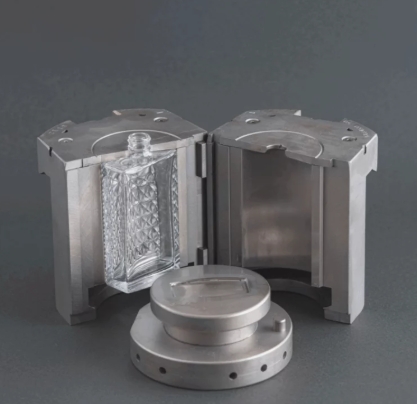

3. Mold Fabrication

Skilled professionals employ CNC machinery along with durable materials like cast iron or steel to create tailored molds that meet exact specifications.

4. Sample Production

A highly restricted production run ensures that the end product meets both aesthetic and functional standards. At this stage, modifications can still be made.

5.Mass Production

Once the samples receive approval, the manufacturer can commence large-scale production using IS machines, accompanied by thorough quality assessments.

Partnering with a respected company like Valiant Glass ensures impeccable performance throughout the entire process, supported by transparent communication, professional expertise, and superior outcomes.

Key Design Considerations for Custom Mold Glass Bottles

1. Shape and Ergonomics

The design of a bottle plays a significant role in both the consumer's experience and the brand's perception. Sleek, elongated bottles often convey a sense of elegance and refinement, whereas shorter, sturdier bottles can evoke feelings of reliability and classic craftsmanship. Additionally, it's crucial to consider ergonomics; the bottle should be easy to hold, pour from, and transport.

2. Neck and Closure Type

The design of the closure must align with both the nature of the product and what customers anticipate. Common choices include corks, swing tops, screw caps, and GPI threaded finishes. The type of closure influences not only how easy it is to use the product but also its sealing effectiveness and how long it remains fresh on the shelf.

3. Volume and Fill Level

Glass bottles must adhere to strict volume specifications. Both consumer demands and regulatory standards necessitate accurate fill levels. For example, vodka bottles typically range from 350ml to 1L in size. It’s important that the manufacturer you select utilizes exacting production methods to guarantee uniformity.

4. Color Options

Colors not only boost visual attractiveness but also serve functional purposes. Clear glass, known as flint glass, allows the contents to be visible, while colored options like green, amber, or cobalt blue offer UV shielding and help distinguish between different brands.

5. Surface Decoration and Branding

There are various techniques available for branding your products, such as silk screening, acid etching, frosting, UV spot coating, embossing, hot stamping, and pressure-sensitive labels. These enhancements are crucial for captivating potential customers and conveying your narrative at a quick glance.

Tips for Ordering Your First Custom Mold Glass Bottle

- Define Your Brand Vision: Understand the purpose of your product, identify your target audience, and envision how you want the packaging to reflect your brand's identity.

Collaborate with Expert Developers: Companies like Valiant Glass can support you throughout the journey from concept to launch by offering both technical expertise and creative insights. - Carefully Review Samples: Assess the dimensions, functionality, design, and visual appeal of your product before moving into large-scale production.

- Logistical Planning: Account for production timelines as well as expenses related to international shipping, customs clearance, and potential warehousing needs.

- Consider Sustainability: Reach out to your supplier to explore environmentally friendly practices and recycling options for post-consumer materials.

Conclusion: Custom Mold Glass Bottles as a Strategic Investment

In today's branding landscape, the significance of packaging has reached unprecedented heights. Tailored glass bottles provide a strategic advantage by transforming packaging into a narrative device. This not only fosters emotional connections but also enhances perceived value and supports ongoing brand recognition.

At IDEA Bottles, we excel in converting ideas into striking glass containers that delight consumers and bolster product credibility. Our unique blend of expertise, technical skill, and commitment to sustainability positions us as the perfect partner for brands aiming to create an impactful presence.

Whether you're crafting a premium spirit, redesigning your wine range, or introducing a new line of non-alcoholic drinks, we are here to help you realize your vision in glass.

Explore IDEA Bottles today to view our extensive collection of spirit bottles, wine bottles, and fully customized options tailored to fit any brand's requirements.